Two-Phase Flow

Flows with two or more phases are commonly found in various industrial processes. In the case of oil production, for example, multiphase flow patterns occur both in the wells and in the lines that connect them to the platform. Thus, it is common for the mixture to be transported through long distances before the phases are separated. This emphasizes the importance of studying the properties of such flows.

Different geometrical arrangements of the interfaces between fluids can occur depending on operational conditions (flow rate, pressure, temperature), transport line configuration (dimensions, inclination) and fluid properties (density, viscosity, interfacial stresses). The combination of these characteristics determines the flow pattern, which can be annular, wavy, stratified, or slug.

The Fluids Engineering Laboratory has been developing non-intrusive optical techniques for visualization and field measurements in two-phase flows, in order to study the different patterns and phenomena observed in practical applications. Laser-induced fluorescence (LIF), particle image velocimetry (PIV), pulsed shadow (PST) techniques, as well as digital image processing and index of refraction matching methods have been combined to yield innovative results in this research field (Measurement Techniques).

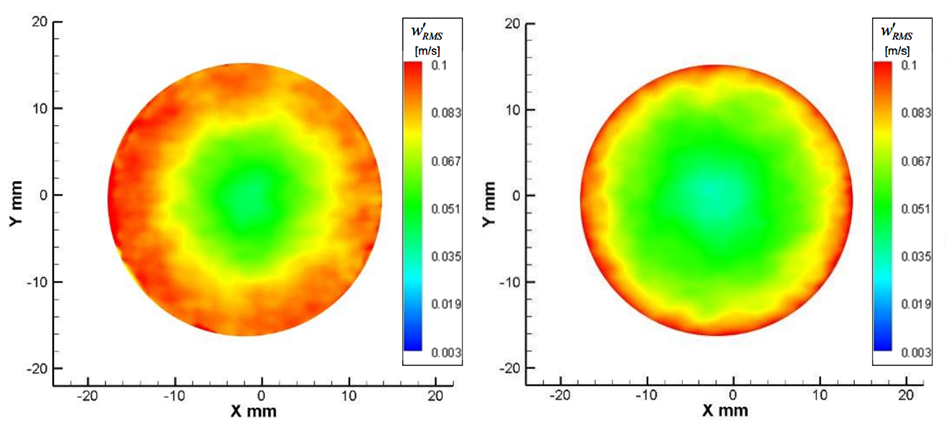

Turbulence and Drag Reduction

Countless are the applications in which it is desirable to attain some reduction in the skin friction drag caused by the flow of a fluid in contact with surfaces. It is the case for aeronautical and naval design, pipeline systems, among others. Considering the potential increase in efficiency and the environmental advantages, the development of methods that can provide drag reduction becomes essential.

The addition of small amounts of long-chain polymer molecules to the flow and the use of modified surfaces are two of the methods employed in the industry that can achieve considerable levels of skin friction reduction in turbulent flows. The physical comprehension of these phenomena is important not only for their application in engineering situations but also to help elucidate some mechanisms of academic interest concerning the turbulence itself.

At LEF, these two forms of achieving drag reduction in turbulent flows – polymer addition and use of surfaces with riblets – are experimentally addressed in channel flows. A water tunnel with dimensions 0.80 m x 0.60 m x 4 m is also part of the infrastructure, and experiments with controlled turbulence level can be conducted in it, whether with hot wire anemometry or optical techniques (Measurement Techniques).

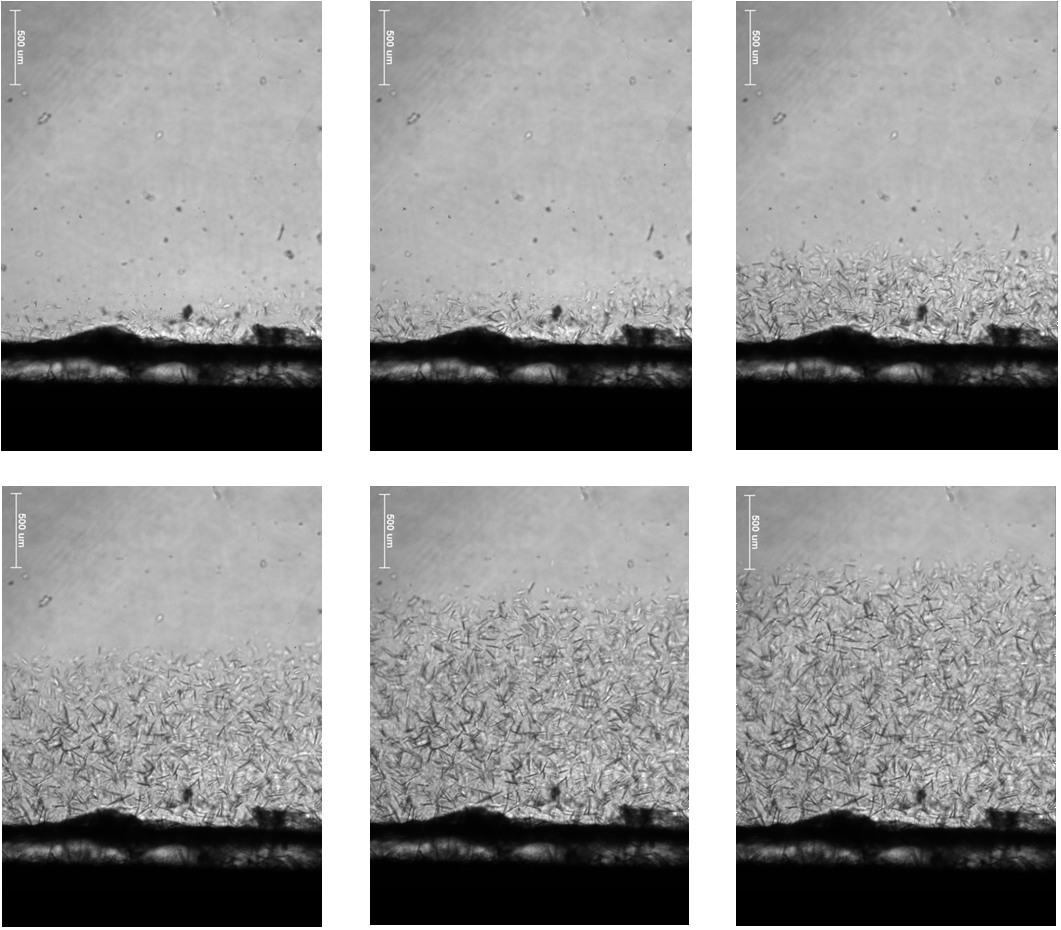

Flow Assurance

In the oil industry, the term flow assurance refers to the set of practices that aim to ensure the integrity of elevation and transport systems, allowing the free flow of the transported fluids. These practices encompass prediction, prevention, and mitigation of problems that can occur from the wells up to the processing units, such as the formation of wax and hydrate deposits, equipment impairment in the presence of undesirable multiphase patterns such as slug flow, pipeline corrosion due to detaching of the liquid film in annular two-phase flow, among others.

Examples of preventive measures are the use of thermal insulation to avoid deposition of organic material in the lines, and use of internal coating. The use of PIGs for deposit removal, on the other hand, is an important mitigation tool when avoiding the problem in the first place is not possible.

Since 2005, flow assurance has been an important topic of study at the Laboratory of Fluids Engineering, supporting the oil and gas sector and also generating academically interesting challenges. The main topics approached in the laboratory are heat transfer and thermal insulation in pipelines, wax deposition, and the flow of heavy oils with temperature-dependant viscosity. The dynamics of mulitiphase flows, whose comprehension is also important in the field of flow assurance, constitutes by itself a broad line of research at LEF (Two-Phase Flows).

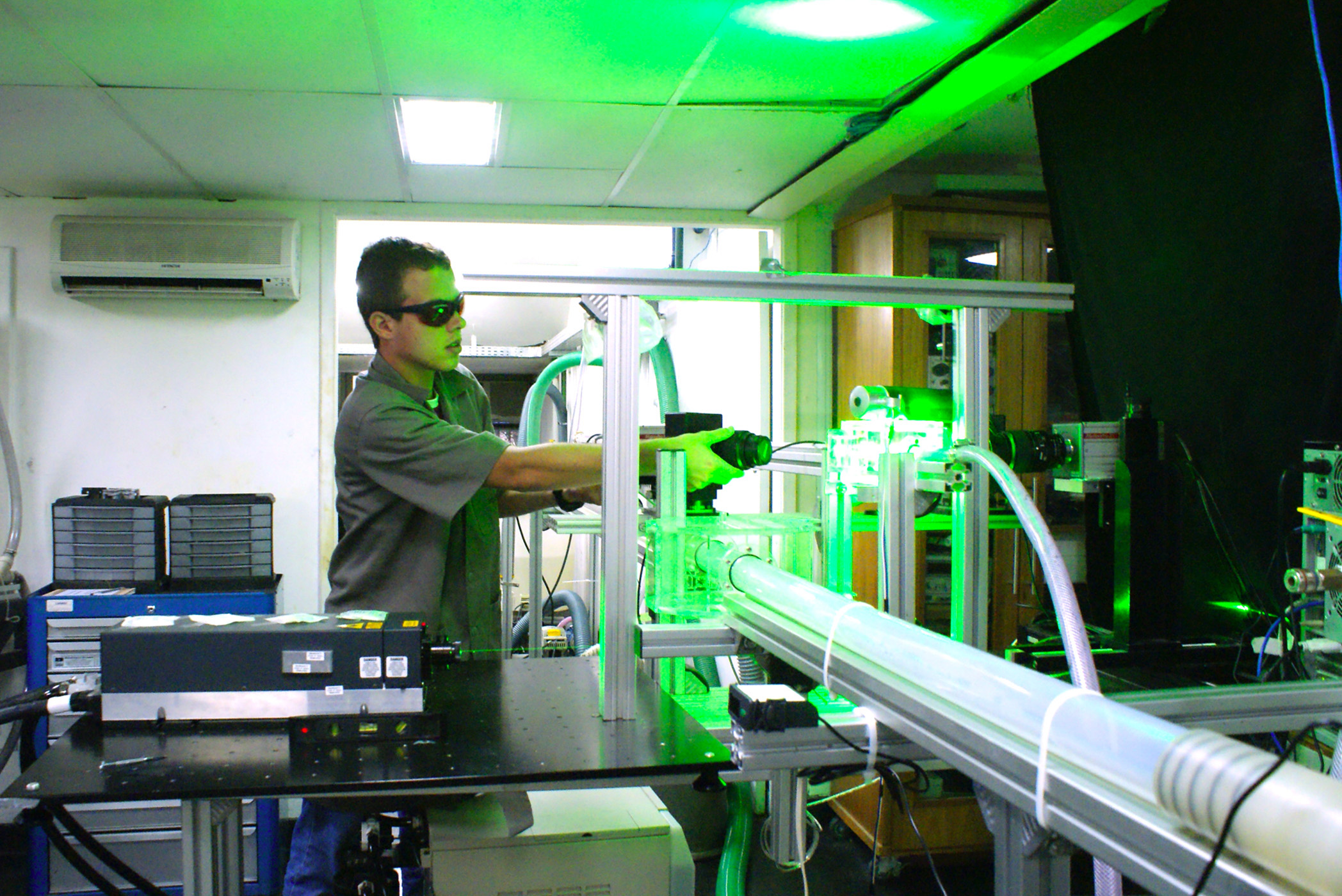

Measurement Techniques

Various optical techniques for visualization and velocity field measurements are commonly used at the Laboratory of Fluids Engineering. Those are advanced techniques which enable the detailed analysis of complex flows, whether they are turbulent, two-phase or through unusual test section geometries.

Each of the techniques offers particular implementation challenges, and all of them involve some degree of digital image processing and the development and application of algorithms (for example, 2D or 3D spatial correlation or particle tracking algorithms), which should be frequently optimized. Hence, the issues concerning those techniques are also an object of constant study and testing.

Cardiovascular Engineering

Cardiovascular diseases represent the main cause of mortality in our country. Moreover, the associated morbidity implies precocious disablement of the population, resulting in higher expenditure for health care and social security systems. Factors such as population growth and aging, along with inadequate eating habits, sedentary lifestyle and smoking, reinforce a disturbing trend in the current scenario.

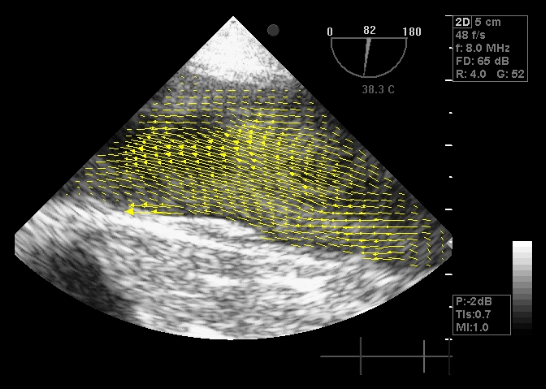

In order to analyze the influence of risk factors and prevention, the constant development of early diagnosis tools and the better knowledge of cardiovascular pathophysiology are needed. In this regard, in vivo experiments are conducted at LEF with the Echocardiography Particle Image Velocimetry (Echo-PIV) technique. Its goal is to measure in detail the blood flow field inside the cardiac chamber, arteries, and veins. Images of echocardiography exams from certain patients are selected, and image processing techniques are applied in order to measure velocity, vorticity, and shear rate fields in specific regions.